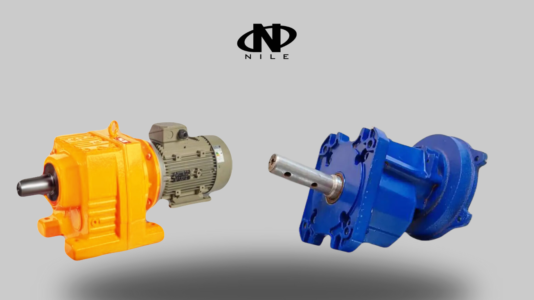

Introduction of types of industrial gearboxes The purpose of using industrial gearboxes is to change the amount of torque and speed received from the engine. The gearbox consists of 2 main parts, the shaft (axis) and the gear wheel. By connecting and engaging these 2 parts, the gearbox works and the conversion ratio, torque and output speed are obtained. In each type of gearbox, the positioning of the shaft and gears is different, and this has led to the design and production of different models of gearboxes for different tasks. If you want to have more and more specialized information about the design, components and performance of industrial gearboxes, read the article What is an industrial gearbox? In this article, we divide and examine industrial gearboxes based on various features.Classification based on the type of gear: helical gearbox, helical gearbox, solar gearbox, cranial pinion gearbox, conical gearbox. Classification based on axis: direct shaft, parallel shaft, lateral shaft. Gear At first, we will check the gearboxes based on the type of gear. Helical gearbox is called helical gearbox due to its appearance, placement and movement of the gears relative to each other. The helical gearbox is made of at least 2 gears; The first gear, which is cylindrical, is the spiral shaft, which is also called Mardon, and the other is a circular gear, which is called brass gear.The input force enters the Mardon, which is the driving member, then it causes the rotation of the circular or movable gear. Usually, the material of the Mardon gear is a steel cylinder, which is more resistant to the load, pressure, and heavy incoming blows, and the material of the circular gear is made of brass, so that it works smoothly and smoothly. This model is known for its low consumption and low speed, so that it can achieve a conversion ratio of 1 to 100 in a small space.For this reason, it is used in situations where we want a significant reduction in speed and a high torque increase. The advantage of this gearbox is that Mardon can rotate the brass gear, but not the other way around. This structure is suitable for when the gears need to be locked or the gearbox should not rotate in the opposite direction. This feature is called self-locking feature. Types of helical gearboxes In the following, we will get to know the types of helical gearboxes: Book gearbox or cubic gearbox: NRV and NMRV series Circular helical gearboxes: VF and MVF series Flanged helical gearboxes: VF FC and MVF FC series NRV and NMRV gearboxes in cases where Low output speed and high torque are needed, they are used. Because of their appearance, they are also called manual gearboxes or cubic gearboxes. The difference between NRV and NMRV is in their input type.NRV is shaft input and NMRV is flange and hollow shaft input. Book or cubic gearbox is produced in the form of a stand. The VF and MVF gearboxes of these models are structurally similar to the previous category, and their difference is in their appearance, which is also called a circular helical gearbox. The difference between VF and MVF is the same as the previous category in their input and output types. VF model is input with shaft and MVF model is input with flange or hollow shaft. VF and MVF gearboxes are designed with a base. VF FC and MVF FC gearbox. The word FC, which is next to the names of the two VF and MVF models, actually indicates the difference in appearance between these two gearbox models. In VF FC and MVF FC gearboxes, a flange is used for the base of the gearbox, which is called a flange base. Helical gearbox The name of this gearbox is derived from its type of gear. Spiral or helical gears are used in this gearbox, which have high power tolerance and high power transmission. Usually, the number of helical gears in the gearbox is even. Types of helical gearboxes are among the most used due to the characteristics of helical gears, and for this reason, they are used in different gearboxes with different designs. Helical gearboxes are produced with or without a base and with different input and output shafts, hollow shafts and flanges, which are shaftsThey are straight, multi-axis and hanging, and we will introduce them below. Direct shaft in the helical gearbox, direct shaft, as its name suggests, the input and output axis are in the same direction and in a straight way, which is the most basic and simple helical model. Multi-axle In multi-axle gearboxes, helical gears and pinion cranks are used, but usually helical gears are used to have high torque.

Introducing types of industrial gearboxes

28

مرداد